When you think of robots, images from movies like “Transformers,” “The Terminator,” or even “Wall-E” probably spring to mind. The ways in which robots really interact with our world are much less dramatic than these action-packed, apocalyptic depictions, but they are playing an increasingly important role in manufacturing and space sectors. This is something University of Connecticut associate professor of electrical and computer engineering Ashwin Dani knows well.

Dani grew up seeing robots in books and on TV, but it wasn’t until college that he began working with them hands-on. As an undergraduate at College of Engineering Pune in India, Dani entered robotics competitions with sensor-controlled toy cars providing him his first real experience with engineering robotics.

His interest continued in graduate school as Dani earned his Ph.D. in mechanical and aerospace engineering at the University of Florida.

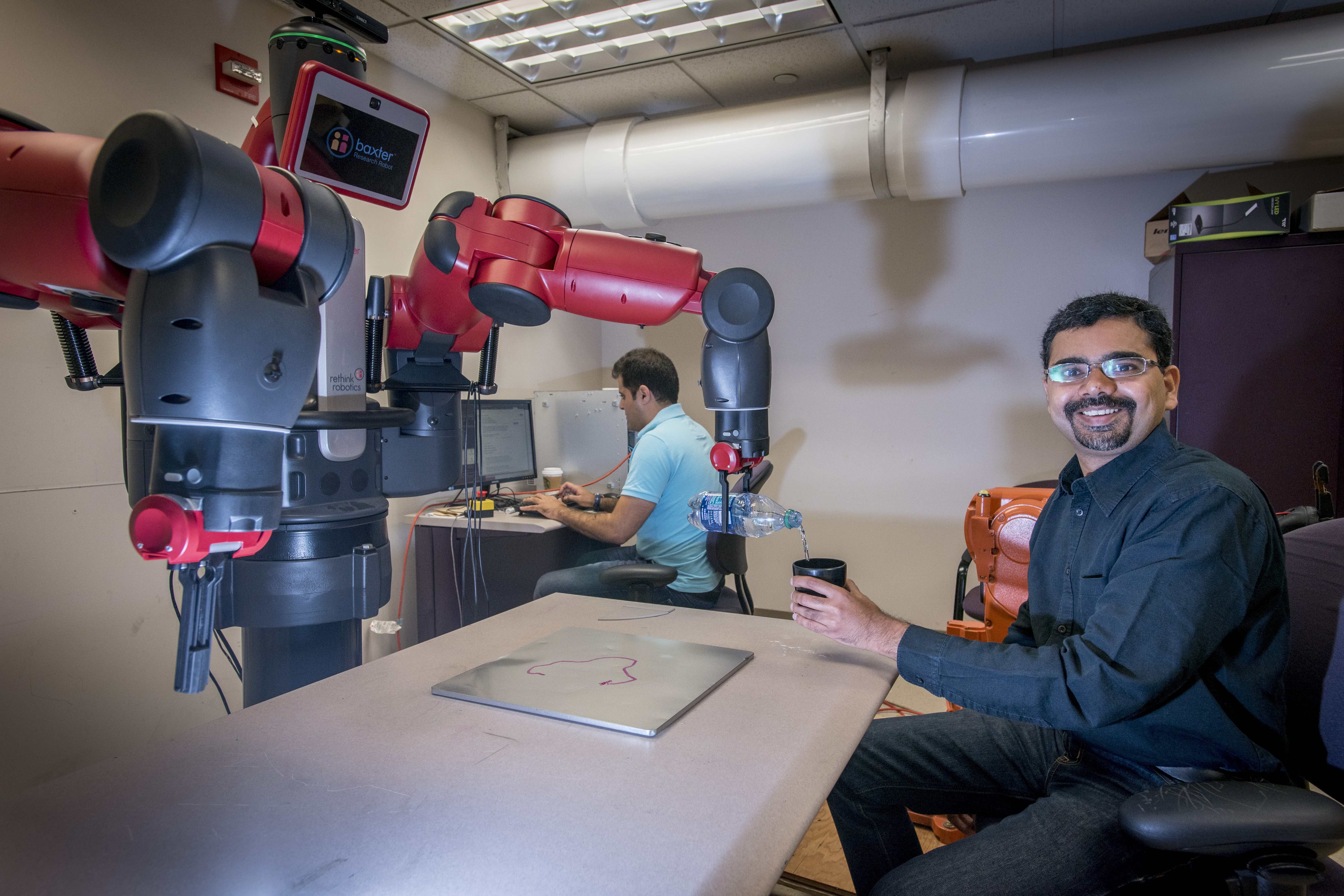

Since coming to UConn in 2013, Dani has worked with a host of industry collaborators to incorporate robotics into manufacturing alongside human workers.

A Symbiotic Relationship

Dani has worked with several major aerospace manufacturers in Connecticut, including United Technologies (now Raytheon Technologies).

“There is a lot of interest, and there are a lot of challenges where robotics would help in terms of efficiency, safety, resiliency, and reliability in the work environment,” Dani says.

Dani emphasizes that his research focuses on how robots can work with people in manufacturing, not instead of them.

These cyber-physical-human systems are becoming more standard in many industries as companies see the benefits of pairing automation with human intellect.

“There is symbiosis between humans and machines,” Dani says. “What people are finding is that a collaborative work environment is in some ways better than complete automation.”

With both people and robots in the room, robots can carry out certain repetitive tasks more efficiently, while workers carry out tasks requiring more human judgment.

Training robots to perform useful tasks can be costly and time consuming. Robot learning from human demonstration is an important aspect of robot training, as it enables operators to “teach” robots different tasks without the need for reprogramming. Dani was recently issued a patent for his “Skill Transfer from a Person to a Robot” technology.

With new advances in machine learning and artificial intelligence, the possibilities for robots in manufacturing are increasing all the time.

“Part of the work is getting people to trust that robots are not harmful, and we can actually work in close proximity with robots by developing a symbiotic relationship,” Dani says.

Seeing Opportunities for Innovation

Dani recently completed a project for the Advanced Robotics for Manufacturing (ARM) Institute automating the wire harness pinning process. Wire harnesses provide a single connection point for multiple wires and direct power to various parts of a larger machine, including cars.

After going into factories and observing their processes, Dani and his collaborators saw a great opportunity for automation in the wire harness pinning step in which they are bundled.

They were able to successfully lower the failure rate of this process and increase the overall efficiency.

Dani will be working on another ARM-funded project automating the taping process for Aerobotix, a company which provides painting robots for military, NASA, aerospace, and general industry purposes.

Before one of Aerobotix’s machines paints something, the areas to remain unpainted need to be covered up with tape. By automating this step, it will be a more efficient and precise process.

Dani has also worked on a physics-informed machine learning project with Pratt and Whitney through the UTC-Institute of Advanced Systems Engineering located at UConn Tech Park.

“It was a fun project where the interaction of machine learning with control systems was applied to large-scale problems in aerospace,” Dani says.

Dani is also part of a NASA-funded institute called the Resilient ExtraTerrestrial Habitats institute (RETHi) to develop resilient habitats that could withstand the harsh conditions on the moon and on other planets.

NASA hopes to establish a prolonged human presence on the moon by 2024: a lofty goal that will require a tremendous effort by a multi-institution team of researchers.

“We are collaborating with world-leading experts in this area through this consortium,” Dani says.

In addition to his work in harsh environments in sky and space, Dani is also working on robotic technologies that could go to the depths of the ocean. He is also conducting manufacturing robotics-related projects under the National Institute for Undersea Vehicle Technology (NIUVT), which is a collaboration between UConn, the University of Rhode Island, and General Dynamics Electric Boat.

Connecting to Industry

As part of the ARM Institute, RETHi, and NIUVT, Dani has been exposed to the challenges and opportunities in different industries across the country.

“Through my work with these national institutes, I get to see the bigger picture of what’s going on with U.S. manufacturing and space sectors, and where the opportunities for robotics and manufacturing are,” Dani says.

Dani’s work deals directly with challenges his industry partners face. The nature of his research allows him to apply scientific concepts to concrete problems and see the solutions implemented in real time.

“I get to actually take the basic scientific and engineering research we do in our labs and that we teach in our classrooms and apply that to a real world problem that exists today in the aerospace industry,” Dani says.

This aspect of his research is also incredibly valuable to the students with whom Dani works. Seeing the abstract concepts they learn in class applied to industry challenges enhances their learning and better prepares them to enter the workforce after graduation.

“As a researcher and an educator, to me, it holds a lot of value and it gives a lot of satisfaction,” Dani says. “It gets students better prepared for jobs and for their future and for their life.”

New Directions

Dani says his work often naturally leads him in new directions. Discovering a solution to one manufacturing challenge can open the doors to other applications.

As robotics becomes an increasingly important part of every manufacturing process, Dani expects his work to continue to take on new and exciting directions as science and industry advance together.

“There are a lot of different opportunities we get, and I’m excited to pursue the artificial intelligence and robotics activities at UConn,” Dani says.

To learn more about Ashwin Dani’s technologies, contact UConn Technology Commercialization Services licensing director, Lindsay Sanford, PhD (lindsay.sanford@uconn.edu).

Follow UConn Research on Twitter & LinkedIn.