Driving Change and Delivering Impact at Scale

NextFlex is helping lead the future of electronics innovation as the nation’s hub for hybrid electronics and manufacturing readiness. As a public–private partnership and manufacturing innovation institute, NextFlex bridges the divide between the lab and the production line for hybrid electronics—transforming groundbreaking research into deployable capabilities that advance U.S. defense, energize domestic industry, and unlock entirely new product possibilities. Thin, lightweight, and innovative designs are reshaping what electronics can do. By merging printed electronics with traditional semiconductor circuits through additive manufacturing, hybrid electronics enable superior functionality, enhanced performance, and ultra-miniature devices that bend, flex, and stretch—realizing advanced systems for communications, navigation, and hardware systems enabled by hybrid electronics such as All-Domain Attritable Autonomous (ADA2) vehicles.

At the heart of NextFlex is a vibrant consortium of manufacturers, innovators, government partners, and educators united by a shared mission: to accelerate hybrid electronics innovation, close the advanced manufacturing workforce gap, and cultivate a sustainable, resilient U.S. electronics manufacturing industrial base. Together, they are building the foundation for a stronger, more connected future.

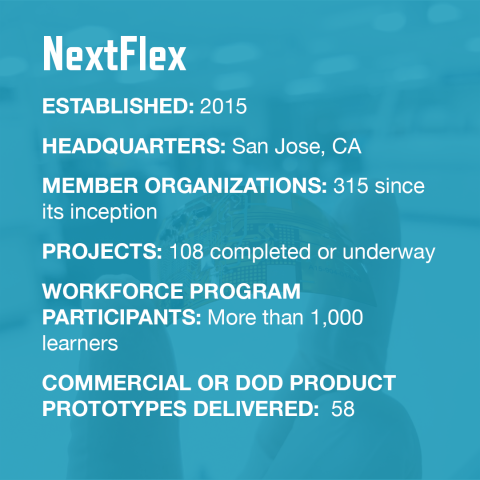

Over the past decade, NextFlex has catalyzed transformation in both technology and talent. With $153M invested in 108 projects, the institute has fueled continuous innovation, fostered member collaboration, and delivered measurable impact for both the Department of Defense and commercial markets. The NextFlex Technology Hub has developed 58 innovative product designs and produced tens of thousands of units, proving the path from concept to production. At the same time, NextFlex is shaping the workforce of tomorrow—engaging more than 25,000 students in hands-on STEM learning, while providing advanced training and technical workshops that empower government, industry, and academia to thrive in a rapidly evolving manufacturing landscape.

NextFlex Achievements

Industrial Base Development

- Technology Roadmaps: NextFlex, together with its members and government partners, has solved 43 technology and manufacturing gaps identified in 11 manufacturing technology roadmaps produced annually by the NextFlex Technical Working Groups. These roadmaps identify critical challenges and guide collaborative projects that accelerate manufacturing innovation, strengthen U.S. supply chain resilience, enable rapid technology transition, and unlock new capabilities in additive, flexible, conformal, and stretchable electronics manufacturing. The Technical Working Groups consist of two types: Manufacturing Thrust Areas, which focus on advancing manufacturing technologies and best practices, and Technology Platform Demonstrators, which focus on applications.

- Precision Rapid Innovation & Scaling Manufacturing (PRISM) Program: Through a grant from the U.S. Department of Defense, Office of Local Defense Community Cooperation, NextFlex is actively bolstering defense innovation and advanced manufacturing ecosystems in Texas through small business development. With these funds, NextFlex supports microelectronics businesses within the Texas defense industrial base by providing access to leading-edge hybrid electronics design, prototyping, and additive manufacturing services through its Technology Hub.

Workforce Development

- FlexFactor®: In collaboration with 35 partners and more than 240 manufacturers, NextFlex has engaged over 25,000 K–12 students in hands-on STEM and manufacturing experiences across 13 states. This scalable model strengthens connections between education and industry, builds the future talent pipeline, and supports the DoD’s workforce readiness and innovation objectives.

- Mil-STTEM: NextFlex and Central New Mexico Community College co-developed and launched the Military Spouse Technical Training for Employment Mobility (Mil-STTEM) program, a hands-on training initiative that equips military spouses with in-demand skills in hybrid electronics and advanced manufacturing. The program expands the skilled workforce, supports employability of DoD family members, and enhances U.S. industrial base resilience. Upon graduation from the bootcamps, participants are connected with potential internship opportunities through state funding or military-serving non-profits.

Project Success Stories

American Made Next-Generation Antennas

Through a partnership enabled by NextFlex, a small business, defense prime, and university co-designed next-generation antennas with improved size, weight, and performance. Now integrated into a military aircraft upgrade, this effort established a U.S.-based supply chain, reduced foreign dependency, and advanced DoD modernization goals.

Commercializing Worker and Soldier Safety Monitoring

NextFlex enabled small business Vigilife to develop and commercialize the first U.S.-made, intrinsically safe wearable heat stress monitor. Now field-tested and entering early Marine Corps procurement, this domestically developed device improves Warfighter safety in hazardous environments while strengthening the U.S. industrial base with dual-use defense technology.

Health Monitoring in Space

NextFlex contributed to NASA’s development of AstroSense, a next-generation wearable sensor for astronaut crew health monitoring. Multi-disciplinary teams from Marshall Space Flight Center, Ames Research Center, and flight surgeons at Johnson Space Center collaborated across multiple design iterations to create and deploy this crew-worn sensor for real-time vital sign monitoring in space.

Q&A with Dr. Daniel Gamota, Executive Director

Leading NextFlex since 2024, Executive Director Daniel Gamota reflects on the institute's 10th anniversary, discussing its history of success and sharing the long-term goals he is most excited to pursue.

What have been the challenges in building your ecosystem?

Building a new industrial base in advanced manufacturing requires trust, alignment, persistence, resilience, and clear mission-aligned value. The biggest challenge has been uniting different stakeholders, including OEMs, SMMs, startups, academia, and government, with unique objectives, risk tolerances, and timelines, around a shared vision. Bridging these divides demands constant engagement, clear demonstration of value, and mechanisms that reduce risk for participants as they adopt emerging technologies.

What are the keys to increasing adoption in your focus area?

Accelerating adoption hinges on delivering demonstrable performance gains, reducing risk, and building workforce readiness. Hybrid electronics deliver clear advantages in size, weight, power, and cost, but these benefits must be validated in defense fielded systems and industrial applications. The key is partnering with DoD programs of record to create early demonstrators that de-risk adoption and equipping SMMs with design and manufacturing capabilities to ensure scalable, resilient adoption.

What accomplishment or impact are you most proud of since joining NextFlex, and why does it stand out to you?

I am most proud of how NextFlex has accelerated the transition of hybrid electronics from laboratory concepts into defense-relevant demonstrators. The NextFlex public-private partnership has delivered rapid, mission-impacting innovation for advanced communications and navigation systems for unmanned aerial vehicles as well as lightweight, wearable systems that enhance warfighter survivability, lethality, and mission performance. NextFlex and its members have generated tangible results that strengthen both national security and the domestic industrial base.

What initiatives or partnerships have been most effective in supporting SMMs?

Our collaboration platform is one of the most effective tools for supporting SMMs. By providing SMMs access to prototyping facilities, prime contractor engagements, and defense-relevant projects, NextFlex assists them in crossing the “valley of death” to insert capabilities into the supply chain. Collaborative projects with primes and Tier 1 suppliers have allowed SMMs to demonstrate capabilities on real defense-relevant programs, giving them a pathway into supply chains they would not otherwise access.

What impact do you hope NextFlex’s work will have on U.S. manufacturing over the long term?

My hope is that NextFlex will be seen as a catalyst for reshaping how advanced electronics are designed and manufactured in the U.S. NextFlex aims to strengthen a domestic, resilient supply chain where SMMs play a central role in producing critical electronics, reducing dependence on overseas electronics sources. I also hope NextFlex continues to be a national resource for educating and inspiring the next generation of manufacturing talent to ensure the U.S. retains technological overmatch and industrial base health.

Looking to the future, what goals or innovations excite you most about NextFlex’s next decade?

I am most excited about scaling hybrid electronics into mass adoption across defense and dual-use markets. In the next decade, the U.S. can see hybrid electronics underpin critical AI-enabled edge systems in aerospace, healthcare, energy, and communications, while simultaneously enabling point-of-need and distributed manufacturing for DoD. My goal is to lead NextFlex to reinforce the U.S. industrial base resilience, accelerate hybrid electronics innovation adoption, and strengthen U.S. technological and advanced manufacturing leadership.

10 Years of Innovation, Collaboration & Education

NextFlex is part of the Manufacturing USA network, which was created to increase U.S. manufacturing competitiveness by connecting people, ideas, and technology. Learn more about 10 areas where NextFlex and the rest of the Manufacturing USA network have made a significant impact since the network’s inception in 2014.