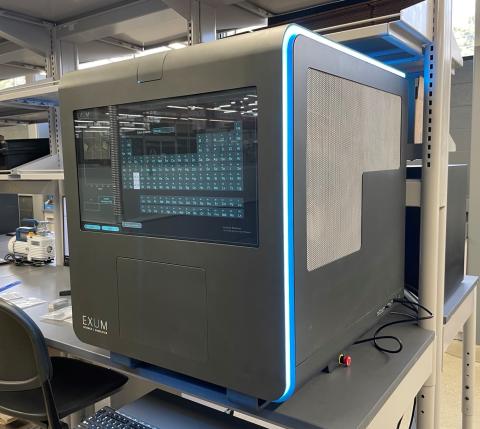

LIFT, the Detroit-based, Department of Defense national manufacturing innovation institute, has announced a new, transformative, high-tech resource has arrived in the metrology laboratory of its 100,000 square foot advanced manufacturing facility: Exum Instrument’s new Massbox, an innovative mass spectrometer specifically designed for ease-of-use on solid materials.

The Massbox is the industry’s first Laser Ablation Laser Ionization Time of Flight Mass Spectrometer capable of trace level detection for virtually the entire periodic table. To strengthen LIFT’s work in designing, building and testing new materials for future components for the Department of Defense and industry, the Massbox rapidly determines the chemical composition of any solid material, from a pressed powder to a solid part. Previously, such testing has been cumbersome, inefficient, with limited scope of elemental results, and generally requiring subcontracting with testing houses. The Massbox changes everything, providing quantitative chemical analysis of metallic, trace, and low-mass (e.g., carbon, oxygen) elements in a single analytical session.

A desktop platform, the Massbox combines Exum’s patented laser-ablation laser-ionization (LALI) source with industry-leading time-of flight (TOF) mass analyzer. LALI utilizes one laser to remove material from a solid sample and a second laser to subsequently ionize neutrals. This process removes many of the elemental fractionation, spectral interferences, and matrix effects that plague other techniques. Plus, its intuitive interface allows a user without chemistry expertise to obtain impactful results with just a few hours of training.