Leading the Charge in Composites Manufacturing Innovation

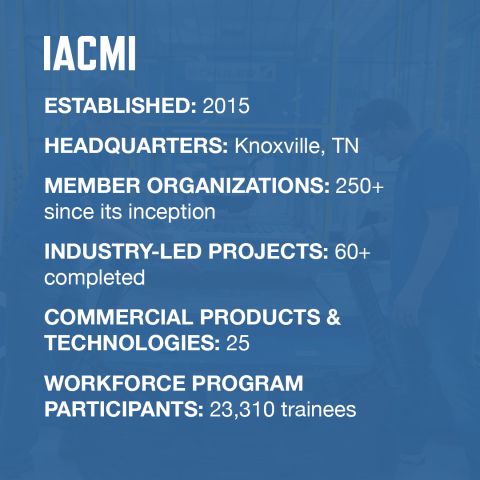

Convene, connect, catalyze. Those three simple yet powerful words have become the credo of the Institute for Advanced Composites Manufacturing Innovation (IACMI) over the past 10 years. Since the Department of Energy announced its launch in 2015, IACMI has convened people and organizations across the composites ecosystem, connected stakeholders to drive innovation forward, and catalyzed advancement and commercialization.

Composites are created by combining various materials, typically a matrix and a reinforcement, providing many advantages in advanced manufacturing. Their use can enhance material strength and durability, make components lighter and more corrosion-resistant, and improve aesthetics and design flexibility. IACMI-supported projects have resulted in significant advancements in wind turbine blades, lighter automobile lift gates, and the development of the world's largest 3D-printed sculpture. With working groups focused on a variety of industry challenges, including aerostructure fabrication, infrastructure and construction, and composites recycling, institute members collaborate on innovative solutions for the entire lifecycle of composite manufacturing and use.

IACMI isn’t just advancing technology—it’s impacting the lives of those involved. Through its signature workforce development programs, the institute has trained more than 20,000 emerging workers in CNC machining, metrology, composites, smart manufacturing, and cybersecurity. Its influence is also evident through its significant economic impact. Over the past decade, the composites ecosystem has benefited from a $400 million investment in scale-up facilities across eight states and $150 million investment in applied research and development – in addition to the commercialization of new products.

IACMI’s Industry Achievements

Ecosystem Development

- Facilities to Incubate New Tech: IACMI empowers its members with access to cutting-edge equipment and expertise through its test bed facilities across eight states, including the Scale-Up Research Facility (SuRF) located in the heart of the automotive industry in Detroit and the Manufacturing Demonstration Facility at Oak Ridge National Laboratory. Over 125 IACMI members have participated in technical projects, leveraging these facilities to drive innovation. A notable example is the Volkswagen liftgate project described below, which utilized IACMI's facilities and partnerships to develop a new material and process, demonstrating the significant impact of access to facilities on industry innovation.

- Industry-Driven Roadmap for Innovation: IACMI has developed a comprehensive roadmap that outlines the industry's toughest challenges and opportunities in areas such as automotive, aerospace, energy, and infrastructure. This roadmap is driven by the collective input of its robust network of over 170 member companies and 4,500 professionals from industry, academia, and federal labs. The roadmap not only identifies key areas for innovation but also facilitates collaborative project calls that connect members across the ecosystem to solve problems and drive advancements.

Workforce Development

- ACE: America’s Cutting Edge (ACE) seeks to fill the urgent and growing need for skilled workers in the U.S. machining and machine tool industry. ACE offers an

-online training module as well as in-person, instructor-led training—all at no cost. The program, launched in 2020 with Department of Defense funding, now has 42 ACE machining training centers in 14 states and has trained over 16,000 aspiring machinists and engineers representing 50 states, preparing them to join the manufacturing workforce. - METAL: METAL (Metallurgical Engineering Trades Apprenticeship & Learning) is shaping the next generation of innovators and builders in casting and forging. The program is designed to create a national training network that will sustain the metals workforce through 2050. It has hub locations in Pennsylvania, Ohio, Alabama, Michigan, California, and Tennessee as well as an online training course. METAL focuses on engaging people from “K to gray” through STEM events, workshops, bootcamps, internships, college certifications, and apprenticeships.

- InnoCrate: InnoCrate kits offer K-5 teachers an easy way to teach students about STEM and composites engineering. Created by professors at the University of Tennessee and led by IACMI, the kits are being used in pilot schools across the country. Activities like making silly putty from scratch and building an Eiffel Tower out of newspapers are fun for students, while teachers gain a simple, turnkey tool to help explain concepts aligned with state standards. Each kit includes curriculum, videos, and all necessary supplies.

IACMI Project Success Stories

Improved Liftgates that Make Vehicles Lighter

An IACMI-sponsored project team helped Volkswagen of America redesign and validate a compression-molded composite liftgate for SUVs. This innovative new design reduced the weight by 35 percent and lowered its recurring cost by 9 percent compared to the steel baseline. Technological advances from this research are now being used across multiple VW platforms, including the new VW ID Buzz EV.

From Bikes to Hydrogen: Scaling Nanotube Innovation Across Industries

IACMI helped scale vertically aligned carbon nanotube (VACNT) technology from high-performance mountain bikes to advanced aerospace and energy systems. First applied to Santa Cruz downhill bikes, the technology reduced wheel failures by up to 80%. The technology was then evaluated for electric vertical take-off and landing aerostructures to produce stronger, faster-to-manufacture parts and cut de-icing costs by at least 67%. Now, partners including Airbus and Joby Aviation are exploring VACNT for hydrogen storage tanks to enhance safety and efficiency in next-generation air mobility. This is how early R&D in this space with IACMI led to companies like NAWA America expanding in Ohio.

Q&A with Chad Duty, Chief Executive Officer of IACMI

Leading IACMI since 2023, CEO and UT Knoxville Professor Chad Duty commemorates the institute’s 10th anniversary by discussing its legacy of impact and highlighting the innovations he is most excited about for the decade ahead.

What have been the challenges in building your ecosystem?

A well-developed ecosystem is not built easily nor overnight. IACMI’s network extends into a number of application areas and spans the supply chain, from large OEMs to small material suppliers. In 2015, IACMI was founded with that network in mind, leveraging the combined power of core technology partners (UTK, ORNL, Purdue, MSU, UDRI, and NREL) as well as some key industrial partners. Over the last decade, IACMI has worked within that network to develop and de-risk new technologies that could be introduced into the marketplace, which has attracted the attention (and membership) of even more companies interested in collaborating with IACMI.

What are the keys to increasing adoption in your focus area?

Developing new technology (processes and products) is a core focus of IACMI’s innovation efforts. A critical step in this is to work closely with our industrial network to identify critical gaps that can be addressed through the network of IACMI’s capabilities and expertise. As we develop the technology with applications in mind, a critical step toward progress is de-risking those technologies for large-scale industrial use.

What accomplishment or impact are you most proud of since joining IACMI, and why does it stand out to you?

IACMI has been moving forward on several fronts over the last few years. Our workforce development programs (ACE, METAL), funded through the DoD’s Industrial Base Analysis and Sustainment program, have grown dramatically and impacted tens of thousands of participants interested in a career in advanced manufacturing. Our team has developed curricula on a variety of topics, including composites, machining, casting and forging, that are available through both online and in-person workshops. These efforts are critical to meeting the future needs of advanced manufacturing for our country’s economic and national security.

What initiatives or partnerships have been most effective in supporting small to medium-sized manufacturers (SMMs)?

A large percentage (~70%) of IACMI’s industrial members are SMMs. They are particularly attracted to IACMI’s network to gain insight into the major initiatives and advancements occurring throughout the industry as well as to make connections with other companies throughout the supply chain. These interactions are most evident within the environment of our working groups and annual members’ meetings.

What impact do you hope IACMI’s work will have on U.S. manufacturing over the long term?

I’m excited that IACMI is advancing US manufacturing on the two specific fronts of technology development and workforce development, and doing both in partnership with a large industrial network. As we’ve already seen with IACMI’s first decade, there are dozens of new products on the market that have been developed through IACMI projects, and thousands of students are gaining valuable exposure to advanced manufacturing skills. Over the long term, IACMI’s impact on US manufacturing will be those technologies delivered to the marketplace and a strong, qualified workforce.

Looking to the future, what goals or innovations excite you most about the IACMI’s next decade?

IACMI has developed world-class facilities and expertise for advancing composite technology on a number of fronts. Great strides have been made in the automotive, aerospace, and wind energy sectors, but the core technologies involved in these advancements have widespread application in relatively unexplored sectors such as infrastructure, oil and gas, geothermal, and nuclear energy. We are also well-positioned to contribute to the advancement of “smart manufacturing,” with unique capabilities for integrating sensors and on-board intelligence into large-scale manufacturing.

10 Years of Innovation, Collaboration & Education

IACMI is part of the Manufacturing USA network, which was created to increase U.S. manufacturing competitiveness by connecting people, ideas, and technology. Learn more about 10 areas where IACMI and the rest of the Manufacturing USA network have made a significant impact since the network’s inception in 2014.