Manufacturers Provide Added Value as Domestic Suppliers

The response to the COVID-19 pandemic has shown there is a clear ROI in manufacturing PPE in the U.S., economically and for society as a whole. The manufacturing community’s response to the pandemic also has provided a proof of concept that domestic suppliers can provide reliance and added value for items of critical importance to the health of the nation. It may prove to be a tipping point for reshoring.

Manufacturers prior to the pandemic already were dealing with risks of cost-driven outsourcing — such as poor quality, theft of IP, shipping delays and a lack of control. The onslaught of disruptions in the global supply chain has provided opportunities, and the Manufacturing USA network’s public-private investment model has shown how it can perform as a catalyst in spurring economic recovery.

Emerging technologies converged with this urgent demand for PPE to create new possibilities for domestic manufacturing, helping boost public health, strengthen our economy and ensure national security. The pandemic-related projects involved many of the institutes and included:

- Digitizing and streamlining production requirements and instructions for PPE, helping ensure public health and safety

- Compliance testing and quality control

- Product lifecycle management

- An online repository to connect suppliers with customers

The Manufacturing USA network institutions are providing pathways for manufacturers to add more value as domestic suppliers and lower their total cost of ownership. Ultimately this will empower manufacturers to align their supply chain management more closely with their business success.

News

Opportunities

America Makes is proud to announce a new directed project call focusing on Methods for AM Cross-Platform Consistency (AM-CPC) with a $250K funding opportunity provided by the National Institute of Standards and Technology (NIST). One award is anticipated.

The...

NIST invites AFFOA, AIM Photonics, America Makes, ARM, BioFabUSA, BioMADE, CESMII, CyManII, IACMI, LIFT, MxD, NextFlex, PowerAmerica, RAPID, & REMADE Manufacturing USA institutes to propose high-impact projects designed to fund awards for research, development, and testbeds to prevent, prepare for, and respond to coronavirus.

Please note that...

The High Performance Computing for Energy Innovation (HPC4EI) Program, managed by Lawrence Livermore National Laboratory (LLNL), has issued a special solicitation seeking industry partners to collaborate with the Department of Energy’s (DOE’s) national laboratories on projects to improve manufacturing processes.

This special solicitation invites...

External News

The National Institute of Standards and Technology (NIST) intends to announce a competition for a new Manufacturing USA institute. The expected competition will seek to establish a Manufacturing USA institute focused on using artificial intelligence (AI) to improve the resilience of U.S. manufacturers. The U.S. Government intends to enter into a...

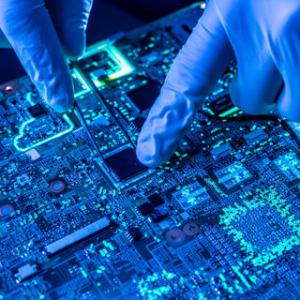

Today, leaders from the Departments of Commerce, Defense, and Energy; and the National Science Foundation; and the Chief Executive Officer of the National Center for the Advancement of Semiconductor Technology (Natcast) gathered at the White House to announce over $5 billion in expected investment in the CHIPS R&D program, including the National...

The National Institute of Standards and Technology released a notice of intent Thursday for an open competition on digital twins for semiconductor manufacturing, packaging and assembly.

According to the Federal Register posting, the CHIPS Research and Development Office seeks to establish “one (1) Manufacturing USA Institute focused on” digital...

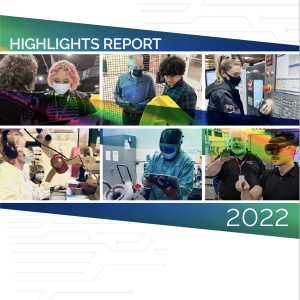

Today, the Biden-Harris Administration will announce new commitments to workforce development from the Advanced Manufacturing Workforce Sprint. The Sprint, which First Lady Jill Biden announced in May and the Administration kicked off in October, is an intensive drive to build a diverse, skilled pipeline of workers for good advanced manufacturing...

Manufacturing is part of the backbone of America’s economy and our communities. And the past year since the passage of the Inflation Reduction Act has shown us that investing in a sustainable future can make manufacturing’s presence in America even stronger. Already, the private sector has put forward more than $110 billion in new manufacturing...

Dr. Steven Wax, performing the duties of the Assistant Secretary of Defense for Science and Technology, recently concluded a visit to two of the Department of Defense's nine Manufacturing Innovation Institutes. The visit included both the Advanced Regenerative Manufacturing Institute/BioFabUSA and Advanced Functional Fabrics of America.

MIIs were...

They are 16 creators at heart. One creates automation systems for manufacturers. Another designs software for photonics. One helps create high-tech careers in robotics, another in cybersecurity, and a third in the emerging field of remanufacturing. One went to prison and turned his life around to make a six-figure salary in CNC machining.

Several...

In support of President Biden’s Investing in America agenda, a key pillar of Bidenomics, the U.S. Department of Energy (DOE) announced $22 million to 12 state-run programs to accelerate smart manufacturing at small- and medium-sized facilities. Funded by the President’s Bipartisan Infrastructure Law, the State Manufacturing Leadership Program aims...

As Beijing has become Washington’s overriding challenge of the twenty-first century, the Chinese leadership has made clear that it aims to displace the United States as the world’s technological and economic superpower. This form of competition has no historic precedent. China has a much larger and more technologically advanced economy than did the...

I have to say that I’m flabbergasted. In fact, I don’t think it would be unfair to say that rarely has my flabber been quite so gasted. The reason for my current state of high-gast is that I just received some frabjous intelligence with respect to enhancing our manufacturing capabilities here in the USA.

One of the things that’s made me...

Manufacturers Provide Added Value as Domestic Suppliers

The response to the COVID-19 pandemic has shown there is a clear ROI in manufacturing PPE in the U.S., economically and for society as a whole. The manufacturing community’s response to the pandemic also has provided a proof of concept that domestic suppliers can provide reliance and added value for items of critical importance to the health of the nation. It may prove to be a tipping point for reshoring.

Manufacturers prior to the pandemic already were dealing with risks of cost-driven outsourcing — such as poor quality, theft of IP, shipping delays and a lack of control. The onslaught of disruptions in the global supply chain has provided opportunities, and the Manufacturing USA network’s public-private investment model has shown how it can perform as a catalyst in spurring economic recovery.

Emerging technologies converged with this urgent demand for PPE to create new possibilities for domestic manufacturing, helping boost public health, strengthen our economy and ensure national security. The pandemic-related projects involved many of the institutes and included:

- Digitizing and streamlining production requirements and instructions for PPE, helping ensure public health and safety

- Compliance testing and quality control

- Product lifecycle management

- An online repository to connect suppliers with customers

The Manufacturing USA network institutions are providing pathways for manufacturers to add more value as domestic suppliers and lower their total cost of ownership. Ultimately this will empower manufacturers to align their supply chain management more closely with their business success.

News

Opportunities

America Makes is proud to announce a new directed project call focusing on Methods for AM Cross-Platform Consistency (AM-CPC) with a $250K funding opportunity provided by the National Institute of Standards and Technology (NIST). One award is anticipated.

The...

NIST invites AFFOA, AIM Photonics, America Makes, ARM, BioFabUSA, BioMADE, CESMII, CyManII, IACMI, LIFT, MxD, NextFlex, PowerAmerica, RAPID, & REMADE Manufacturing USA institutes to propose high-impact projects designed to fund awards for research, development, and testbeds to prevent, prepare for, and respond to coronavirus.

Please note that...

The High Performance Computing for Energy Innovation (HPC4EI) Program, managed by Lawrence Livermore National Laboratory (LLNL), has issued a special solicitation seeking industry partners to collaborate with the Department of Energy’s (DOE’s) national laboratories on projects to improve manufacturing processes.

This special solicitation invites...

External News

The National Institute of Standards and Technology (NIST) intends to announce a competition for a new Manufacturing USA institute. The expected competition will seek to establish a Manufacturing USA institute focused on using artificial intelligence (AI) to improve the resilience of U.S. manufacturers. The U.S. Government intends to enter into a...

Today, leaders from the Departments of Commerce, Defense, and Energy; and the National Science Foundation; and the Chief Executive Officer of the National Center for the Advancement of Semiconductor Technology (Natcast) gathered at the White House to announce over $5 billion in expected investment in the CHIPS R&D program, including the National...

The National Institute of Standards and Technology released a notice of intent Thursday for an open competition on digital twins for semiconductor manufacturing, packaging and assembly.

According to the Federal Register posting, the CHIPS Research and Development Office seeks to establish “one (1) Manufacturing USA Institute focused on” digital...

Today, the Biden-Harris Administration will announce new commitments to workforce development from the Advanced Manufacturing Workforce Sprint. The Sprint, which First Lady Jill Biden announced in May and the Administration kicked off in October, is an intensive drive to build a diverse, skilled pipeline of workers for good advanced manufacturing...

Manufacturing is part of the backbone of America’s economy and our communities. And the past year since the passage of the Inflation Reduction Act has shown us that investing in a sustainable future can make manufacturing’s presence in America even stronger. Already, the private sector has put forward more than $110 billion in new manufacturing...

Dr. Steven Wax, performing the duties of the Assistant Secretary of Defense for Science and Technology, recently concluded a visit to two of the Department of Defense's nine Manufacturing Innovation Institutes. The visit included both the Advanced Regenerative Manufacturing Institute/BioFabUSA and Advanced Functional Fabrics of America.

MIIs were...

They are 16 creators at heart. One creates automation systems for manufacturers. Another designs software for photonics. One helps create high-tech careers in robotics, another in cybersecurity, and a third in the emerging field of remanufacturing. One went to prison and turned his life around to make a six-figure salary in CNC machining.

Several...

In support of President Biden’s Investing in America agenda, a key pillar of Bidenomics, the U.S. Department of Energy (DOE) announced $22 million to 12 state-run programs to accelerate smart manufacturing at small- and medium-sized facilities. Funded by the President’s Bipartisan Infrastructure Law, the State Manufacturing Leadership Program aims...

As Beijing has become Washington’s overriding challenge of the twenty-first century, the Chinese leadership has made clear that it aims to displace the United States as the world’s technological and economic superpower. This form of competition has no historic precedent. China has a much larger and more technologically advanced economy than did the...

I have to say that I’m flabbergasted. In fact, I don’t think it would be unfair to say that rarely has my flabber been quite so gasted. The reason for my current state of high-gast is that I just received some frabjous intelligence with respect to enhancing our manufacturing capabilities here in the USA.

One of the things that’s made me...