Technology architect, global tourist, local cyclist

Maria Araujo thinks of her role as Director of Advanced Technology at Johnson & Johnson Service, Inc., as leading research and development for the pharmaceuticals and medtech supply chains. Technology is a driver in almost every step of operations, from the manufacturing of pharmaceuticals and medical devices all the way through the delivery to end users.

“I’m looking at the future of our supply chains, what gaps we have, and identifying what ways can technology help close those gaps,” she said. “But I’m also looking at how we can reimagine certain ways we do things. What are new things we can do? It’s a future-looking job, but you also have to have an eye on the present to understand limitations.”

Maria has expertise in sensors, IIOT (industrial internet of things), advanced materials, and robotics, which she is putting to use in helping design technology architecture. For example, she collaborates closely with the supply chain robotics teams to bring more perception and intelligence to robotic solutions.

She views much of life through discovery, connections, and possibilities - which helps explain her love for travel and finding time to ideate. Maria sees herself inspiring people to want to innovate by helping coworkers imagine new possibilities as they merge technology, creative thinking, and business. She follows a phased innovation model (define, explore, develop, test and scale) to ensure innovations are grounded on real needs as well as aligned with overall business strategic priorities. “If the need or opportunity is clear as well as its business value, stakeholder buy-in will be organic,” she said.

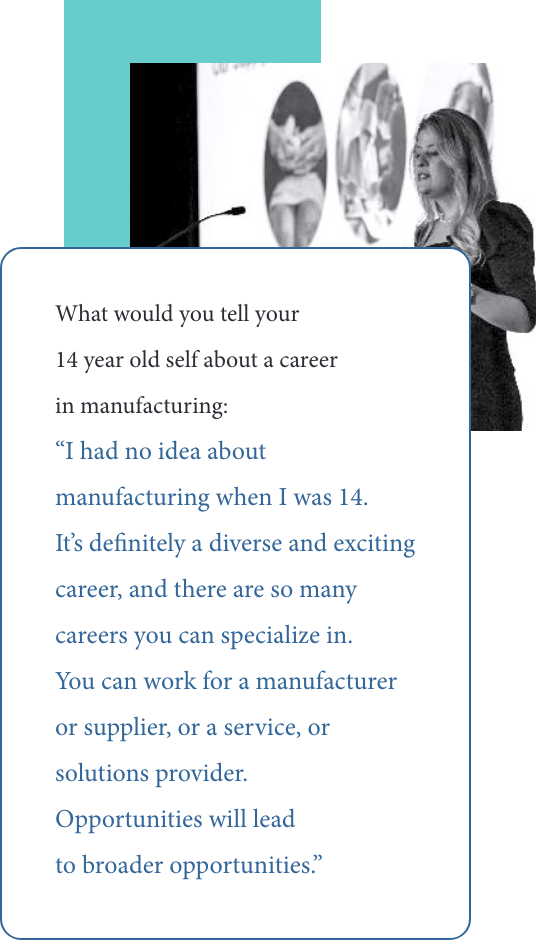

“It’s definitely a high-tech field. Most people today when they think of tech jobs they think of Google or Apple. But manufacturing has many types of high-tech roles.”

A Varied Background Led Her to Technology Architecture

Maria was born and raised in Brazil and came to the U.S. to attend UCLA and study electrical engineering. She started her career at Honeywell Aerospace, and her next stop was at the Southwest Research Institute (SwRI) in San Antonio, where she still lives with her husband and two children. She has worked in aerospace, space, automotive, electric power, oil & gas, and now healthcare.

She says her varied experience has helped her greatly as she has applied solutions from other industries to be used in medical devices, pharmaceuticals, and logistics. But her foundational experience was on the applied research and development side.

“I was designing, developing and testing complex systems, so I had to learn and understand the problems to be solved and systems,” she said. “Now I’m in more of an architect role.”

Working on the Leading Edge of Innovation

She loves the variety in her job and how it is at the edge of execution and innovation — not a theoretical job. It’s ultimately about seeing the results. “It’s never the same every day,” Maria said. “There is no routine. I’m constantly learning. That’s what makes the job very exciting.”

“I have the opportunity to influence and set the direction here. If we develop this type of capability, we can do X.”

Maria has a global role. Johnson & Johnson has more than 136,000 employees working across more than 260 operating companies located in 60 countries around the world. She was at five Johnson & Johnson sites in the first two months of 2023. “You see a lot in manufacturing, in people, and in cultures,” she said.

Developing an Expertise in Robotics

Maria has worked closely with the ARM Institute, of the 16 institutes in the Manufacturing USA network, to implement robotic solutions in manufacturing and logistics. The institute ecosystem, funded in part by the Department of Defense, leverages research from major universities and other institutes to work on projects from member companies in the private sector.

Johnson & Johnson also is a member in three other network institutes: CESMII (Smart Manufacturing), NIIMBL (Biopharmaceutical Manufacturing), and REMADE (Sustainable Manufacturing).

“Innovation institutes play a key role in helping accelerate the technology adoption,” she said. “The model of grant funding and membership access allows manufacturers to invest in things and try things that they would not be able to do on their own. It’s either too risky or costs too much money. The consortium model allows manufacturers to share learnings and successes. They can join forces to solve bigger problems.”

Maria points out how commercial robots are quickly evolving from performing tasks with little variations — like moving pallets along fixed paths and picking items with predictable shapes — to leveraging AI to handle increasingly more complex tasks, such as manipulating items of various shapes and sizes and dealing with unpredictable obstacles and scenarios.

A Different Paradigm for Domestic Manufacturing

Maria sees the impact she and Johnson & Johnson, are having primarily in two ways: through customers and within the manufacturing industry. She says innovation efforts start with how to leverage technology to be more customized for end users.

“It’s all about delivering our product in the best, most timely way possible,” she said. “How do we not only give people what they want, but predict what they are going to want?”

It’s inspiring when those impacts intersect, such as with the growing area of vein-to-vein logistics for cell and gene therapies. Healthcare providers can now take a sample from a person, treat it, and return it to the same individual. It requires logistics systems that increase shipment traceability and enable more sophisticated monitoring.

“There is a different paradigm for domestic manufacturing with the rapid advances in technology — machine learning, data science, advanced sensing, computer vision — combined with the advanced reach from social media,” Maria said. “The opportunity is great to get involved in something that is going to have a big societal impact.”

She Can’t Wait to Get On the Road Again, or the Cycling Path

Maria loves to travel and learn about different cultures, and she says she is fortunate that her job has taken her to many countries. She’s excited about an upcoming trip with her family to Italy, but her favorite destination is Maui, which she has visited three times. On one trip, she and her husband hopped in the car with their snorkeling gear and spent the day going from beach to beach, snorkeling at each.

When at home in San Antonio, she enjoys being outside as much as possible, whether it’s going to the beach or pool (and maybe swimming 10 laps) or cycling. She and her husband ride on the city’s extensive system of bike trails for about nine months of the year, with two or three outings per week. They ride 15 to 20 miles, which gets them far enough away from home for it to feel like an outing and enough exercise for a sense of accomplishment.

“It’s good bonding time, or I can get into my zone and listen to music, think, and not be on my phone or computer. It’s a good time to reflect.”

She says cycling also helps her brainstorm as she often finds herself thinking about how to solve a current challenge or about long-term strategies to push the boundaries of technology.