Team Player, Biofabrication Tech, Home Cook

Alex Nop’s path into biomanufacturing wasn’t traditional, but it was intentional. After working at BAE Systems, a Department of Defense contractor focused on mechanical and industrial manufacturing, he felt drawn to a career that combined advanced technology with the chance to make a difference in people’s lives. That interest led him to apply for the very first Biofabrication Technician Registered Apprenticeship Program at the Advanced Regenerative Manufacturing Institute (ARMI). BioFabUSA, a program of ARMI, makes practical the scalable, consistent, and cost-effective manufacturing of cell-based products and trains the U.S. advanced biomanufacturing workforce.

Introduced to the program through a local community organization that helps individuals overcome employment barriers, Alex started his journey in the fall of 2023. The pre-apprenticeship combined technical classroom instruction with hands-on training in a growing field. For Alex, it was the ideal blend—uniting his background in advanced manufacturing with a newfound passion for the medical field.

Throughout his training, Alex rotated through labs focused on operations, process development, deep tissue characterization, and data analysis. He not only developed technical skills but also built a reputation as a dependable team player, someone always ready to help, receive feedback, and contribute meaningfully. His hard work paid off when he was offered a full-time bioprocess technician position on the Process Development team at ARMI | BioFabUSA..

Today, Alex supports stem cell work in the lab, handles daily tasks like media changes and cell passaging, and jumps in wherever he’s needed—from lab bench duties to gas tank changes. He’s earned multiple certifications along the way, including a Microelectronics Certificate from Nashua Community College (NCC) and cell culture skills from the University of New Hampshire. Alex’s journey shows how curiosity, determination, and hands-on experience can build a meaningful career in biomanufacturing, which makes him a Modern Maker.

Q&A with Alex

How did you find your way to working in advanced manufacturing?

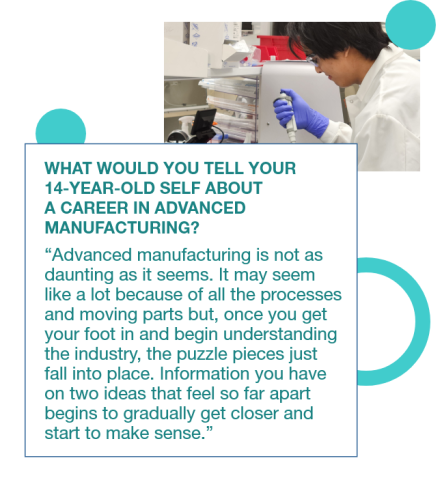

I found my way into advanced manufacturing by getting help from an organization called MyTurn. At the time I was personally struggling to find a way into a professional career but, I heard about an opportunity to learn "Microelectronics" from MyTurn through an accelerated boot camp that Nashua Community College (NCC) held. With that opportunity, I was able to learn the industry of advanced manufacturing and was able to get my foot in, which allowed me to confirm a job right after boot camp. The boot camp helped immensely with getting a career in the industry. During it, we were introduced to industry faces whether it be a director of a company or someone knowledgeable, willing to share their experiences with my cohort. It helped me gain well-needed knowledge and the kind of foundation that I took with me through my career. The program gave me a lot of networking skills and insight on how the industry is run behind the scenes and in a way, what to expect. It also gave me the confidence to apply for the Biofabrication Technician Registered Apprenticeship Program at ARMI. If you are looking to get into advanced manufacturing, look around your local area for accelerated programs to gain needed skills or get into job fairs or events that bigger companies are holding to get your name out there and network. It may seem daunting at first, but as you make your way through the industry and gain more understanding and passion for what you are striving for, I am sure you will begin to feel yourself ease into it.

What is the most challenging part of your job?

The most challenging part I would say is keeping up with everything. With so much going on in terms of all the different departments, having clear lines of communication is super beneficial.

What is the best part of your job?

The best part of my job is the camaraderie built within the office. It is nice to just feel comfortable asking questions. It is an amazing feeling to have co-workers who are honest and open to answering any questions I may have. I am always excited to step into the office as I know the positivity in the workplace just brings the energy up. Even when things go wrong, my peers give amazing constructive criticism and how I can improve the process at hand. It just feels nice to have a support system behind you as you work.

What would people be surprised to learn about manufacturing or your role in manufacturing?

I think people would be surprised to hear that I do not have a formal education, such as a degree. From my experience, degrees and higher education are important but there are a lot of ways to gain knowledge and on-the-job training. Being able to specialize in the field you want by taking more classes focused on the skills you want to learn helps as you can apply those skills to your career. It helps to learn with real examples and experiences.

What advice do you have for someone new to the industry or considering manufacturing as a career?

My advice for someone new to the industry would be to just keep an open mind. Being able to morph and adapt to what is expected of you is always helpful, and it shows your willingness to learn and grow. Being open-minded helped me become active within all departments as I was just happy to learn new processes and techniques that I am able to apply throughout my professional career.

What makes you excited to go to work on Mondays?

My coworkers do make my days go by faster than I would think in the best way possible. I genuinely get energy thinking about working with my coworkers because the environment is just amazing. A willingness from all around to teach and bring those around them up brings up the vibes in the workplace and makes everyone around feel welcome to come in with a question and general curiosity.

What are the three most important skills for your job?

Communication is a huge skill I rely on to understand what a co-worker needs from me starts with communication. Being able to understand each other helps greatly when you are both aiming to achieve the same objective.

Flexibility is also a big one that comes to mind. Sometimes, we may have an open day on our calendars, and with that, be prepared to assist with other processes, as helping hands are welcome in the workspace.

Open-mindedness to adapt and pick up new skills for further development. I personally feel good about learning new skills and enjoy the fulfillment of applying them. Learning a new skill one day and applying it the next feels amazing as you begin to understand the work more.

What activity gives you the most energy?

I enjoy all physical activities. I enjoy being active and having a tiny bit of competitive spirit – dribbling a basketball or peppering a volleyball.

What hobbies make you better at your career?

The hobby that helps me with my career is cooking. Recently, I moved into my own apartment and began cooking more in my free time. Cooking allows me to experiment with new recipes and keep myself innovating.

How does the work you do impact the world?

My work impacts the world by using my curiosity for innovation in advanced technologies in regenerative medicine. ARMI | BioFabUSA is looking to change healthcare by treating traumatic injuries and finding cures for chronic diseases. develop treatments and cures for the nation to stop diseases.